Optimizing Rotary Drum Filter Performance Through Maintenance

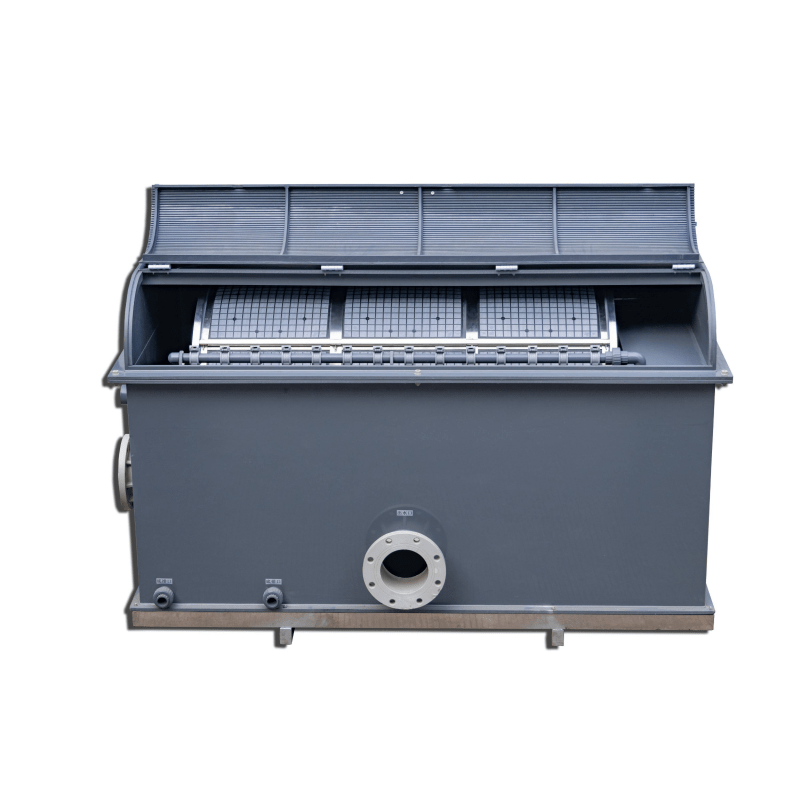

Rotary drum filters play a critical role in numerous industrial processes, providing efficient solid-liquid separation. However, operational downtime can significantly impact productivity and overall efficiency. Implementing systematic maintenance practices is essential to reduce downtime, enhance performance, and extend the life of rotary drum filters. Proper maintenance ensures that filters operate at optimal capacity, minimizes unexpected breakdowns, and supports consistent process output. Companies that prioritize maintenance practices often experience lower repair costs, improved safety, and better resource management.

Understanding Common Causes of Downtime in Rotary Drum Filter Operations

Mechanical Failures

Mechanical failures are among the primary reasons for downtime in rotary drum filter operations. Components such as the drum drive motor, bearings, and gear systems are prone to wear and tear due to continuous operation. Regular inspections can detect early signs of damage, including unusual vibrations, abnormal noises, or irregular rotation speeds. By replacing worn parts in advance, companies can prevent sudden failures that halt production.

Mechanical failures not only disrupt operations but also risk damaging other parts of the filter system. For example, a malfunctioning drum bearing can affect the entire filtration cycle, leading to poor separation efficiency. Maintenance schedules that include lubrication, alignment checks, and load monitoring play a crucial role in mitigating these risks. When mechanical integrity is preserved, the overall reliability of the rotary drum filter is significantly enhanced.

Clogging and Fouling Issues

Clogging occurs when solids accumulate excessively on the drum surface or within the filtration media, reducing throughput and filter efficiency. Fouling, caused by sticky or adhesive materials, can also impair the filter's performance. Regular cleaning and preventative maintenance routines help maintain consistent filtration rates and prevent unexpected downtime.

Preventative measures include scheduled cleaning cycles, monitoring filtrate flow rates, and using chemical treatments when necessary. Maintenance teams should track the composition and volume of filtered materials to adjust cleaning frequencies accordingly. Addressing clogging and fouling issues proactively ensures that rotary drum filters continue to operate smoothly, maintaining both efficiency and product quality.

Seal and Gasket Integrity

Seals and gaskets are vital for maintaining proper filtration and preventing leaks. Over time, these components can degrade due to chemical exposure, pressure fluctuations, or general wear. Regular inspection and timely replacement of seals prevent leaks that can cause operational interruptions.

Proper seal maintenance involves monitoring for signs of wear, inspecting for cracks or deformation, and verifying proper installation. Even minor leaks can result in process inefficiencies, loss of filtrate, or contamination of product streams. Consistent attention to seals and gaskets contributes to uninterrupted operations and reduces unplanned downtime.

Implementing a Comprehensive Maintenance Program

Routine Inspection Schedules

A structured maintenance program starts with routine inspections. Inspections should cover all critical components of the rotary drum filter, including mechanical systems, filtration media, and electrical connections. Documenting inspection results helps track the condition of parts and identify trends that indicate potential failures.

Routine inspections not only prevent unexpected breakdowns but also provide valuable data for predictive maintenance planning. When issues are detected early, corrective actions can be scheduled without disrupting production. This proactive approach ensures operational stability and extends the service life of the equipment.

Preventative Maintenance Tasks

Preventative maintenance encompasses tasks such as lubrication, alignment, cleaning, and replacement of worn parts. By performing these tasks at regular intervals, operators can maintain optimal performance and prevent minor issues from escalating into major failures.

Lubrication of moving parts reduces friction and wear, while alignment checks ensure that the drum rotates smoothly. Cleaning removes accumulated debris and prevents clogging. Replacement of worn bearings, seals, and gaskets minimizes the risk of mechanical breakdowns. Collectively, these tasks improve overall equipment reliability and reduce downtime.

Predictive Maintenance Techniques

Predictive maintenance uses data and technology to anticipate failures before they occur. Techniques such as vibration analysis, thermal imaging, and oil condition monitoring can reveal early signs of mechanical stress or degradation. Implementing predictive maintenance allows maintenance teams to schedule interventions strategically, minimizing the impact on production schedules.

Predictive maintenance also supports efficient resource allocation. By knowing which components are likely to fail, companies can stock spare parts in advance and plan technician availability. This approach reduces emergency repair scenarios, improves operational continuity, and ultimately enhances the profitability of rotary drum filter operations.

Optimizing Filter Media Management

Media Selection and Replacement

The choice of filter media significantly affects the performance of rotary drum filters. Different materials offer varying levels of durability, filtration efficiency, and resistance to fouling. Selecting the appropriate media and replacing it according to operational requirements helps maintain consistent filtration rates and reduces downtime.

Regular monitoring of media condition is crucial. Wear, tear, or damage can compromise filtration quality and cause production delays. Maintenance teams should establish replacement intervals based on usage, material type, and process conditions. Proper media management ensures stable operations and minimizes maintenance-related interruptions.

Cleaning and Maintenance of Filter Surfaces

Filter surfaces must be kept clean to maintain optimal performance. Scheduled cleaning routines remove deposits that could block pores and hinder filtration. Depending on the process, cleaning can involve backwashing, chemical treatments, or manual scrubbing.

Maintaining clean filter surfaces prevents pressure buildup, improves flow rates, and reduces stress on mechanical components. Maintenance personnel should also inspect for media deformation or damage during cleaning to prevent further issues. Effective surface maintenance supports both efficiency and reliability.

Monitoring Filtrate Quality

Monitoring the quality of filtrate provides valuable insights into filter performance. Changes in filtrate clarity, flow rate, or particle retention may indicate issues with the drum filter or the media. Maintenance teams can use these signals to take corrective actions before downtime occurs.

Regular quality checks also help identify trends that could point to early-stage wear or clogging. By addressing issues proactively, companies can maintain consistent product quality and reduce the likelihood of operational interruptions caused by underperforming filters.

Training and Skill Development for Maintenance Teams

Technical Training Programs

Well-trained maintenance teams are essential for minimizing downtime in rotary drum filter operations. Training programs should cover equipment operation, routine inspections, preventative maintenance procedures, and troubleshooting techniques. Skilled personnel can quickly identify and address issues, reducing response time and preventing minor problems from escalating.

Training should also include safety protocols and proper handling of chemicals or mechanical components. Ensuring that maintenance staff are competent and confident in their roles enhances operational reliability and contributes to overall equipment longevity.

Knowledge Sharing and Documentation

Documenting maintenance activities and sharing knowledge within teams supports continuous improvement. Logs of inspections, repairs, and replacements provide valuable data for analyzing performance trends and refining maintenance strategies. Teams that collaborate effectively can identify recurring issues and implement targeted solutions to reduce downtime.

Knowledge sharing also encourages the adoption of best practices and fosters a proactive maintenance culture. By learning from past experiences, maintenance teams can prevent repeat failures and optimize rotary drum filter performance over time.

Leveraging Technology for Training

Technology can enhance maintenance training through simulations, digital manuals, and real-time monitoring systems. Digital tools allow teams to visualize equipment operation, practice troubleshooting scenarios, and access detailed guides on maintenance procedures. Integrating technology into training programs improves knowledge retention and equips teams to handle complex maintenance challenges efficiently.

By combining practical training with technological support, companies ensure that maintenance teams are well-prepared to maintain high operational standards, reduce downtime, and extend the life of rotary drum filters.

FAQ

What is the primary benefit of regular maintenance for rotary drum filters?

Regular maintenance reduces unplanned downtime, enhances filtration efficiency, and extends equipment lifespan. It ensures that all mechanical and filtration components function optimally, preventing unexpected breakdowns and costly repairs. Companies that maintain their filters consistently experience higher productivity and lower operational costs.

How often should filter media be replaced in rotary drum filters?

Filter media replacement depends on the type of media, process conditions, and operational load. Regular monitoring and inspection help determine the appropriate replacement interval. Proactive replacement prevents performance decline and reduces the risk of operational interruptions.

Can predictive maintenance significantly reduce downtime?

Yes, predictive maintenance allows operators to anticipate equipment failures by analyzing performance data, vibrations, and other indicators. By addressing potential issues before they escalate, companies can schedule maintenance strategically, minimizing downtime and improving production continuity.